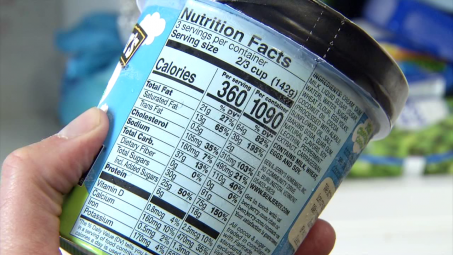

The value of nutrition labels is often overlooked. This is reasonable given that the Nutrition Labeling and Education Act of 1994 made nutrition label mandatory in the United States. Product labels were not issued till very later in other nations.

The Nutrition Labeling and Education Act in the United States and equivalent regulations in other countries were created to assist customers in making better-educated food choices. Consumers may learn more about the food they’re consuming and how healthy it is by looking at the nutrition information on food packaging and other essential information like components, nutrition facts, and nutrition statistics.

However, with excellent nutritional labels come terrible ones. Manufacturing plants all across the globe make nutrition labeling mistakes all the time. Manufacturers suffer financial losses as a result of recalled goods and legal difficulties such as lawsuits filed by consumer organizations or people who nutrition label errors have harmed.

Nutrition labels can damage a company’s reputation in addition to financial concerns. Most customers are unaware of nutrition labeling inaccuracies until too long, resulting in unfavorable publicity for food producers who may mislead consumers into believing they are selling items with dangerous substances or incorrect nutrition data when this is not the case.

Dealing with Food Processing Human Errors

Food manufacturing entails several processes and formulae depending on raw materials like China Bopet Film, BOPP films, etc. It is often not easy to prevent mistakes throughout the manufacturing process.

When designing packaged food recipe ideas, there’s often a risk of human mistakes to occur. Because it was unintentionally inserted instead of another identical item inside the factory, a company’s formula may ask for a component with insufficient nutrition data or no nutrition values.

This might be due to faulty mixing on the manufacturing line, a lack of quality testing undertaken during mixture preparation and testing, or simply a lack of communication between the entities involved in establishing the final ingredient list for each batch prepared.

It’s easy to make a recipe error, combine or examine ingredients incorrectly, or make any variety of faults throughout the production process. Even though a mistake is made, manufacturers must respond rapidly to fix any developing issues. Adjustments may be made using a nutritional info calculator to reduce the total effect.

Processing, Packaging, and Promotional Activities

Product promotions may sometimes contribute to manufacturing problems. When companies take advantage of transitory price cuts in specific commodities, the procurement of materials might be hastened, and quality standards can be neglected. These conditions may lead to errors.

Furthermore, marketing campaigns such as brief discounts may not be considered when constructing nutrition facts panels since these specials do not usually endure for long periods, resulting in food products being sent out without the proper food label information. To assist close this gap, a nutrition facts maker solution is essential.

Manufacturing Process Errors with Equipment

Manufacturers may be forced to employ equipment that isn’t specifically built for the job due to equipment failures. This apparatus may not have been regulated correctly, resulting in inaccurate ingredients and packaging materials readings. So you should get the best quality from the China BOPP film manufacturer.

Impact of incorrect measurement errors on food labeling and packaging

The following are examples of errors caused by improper measurements on printed nutrition labels and food packages:

Modifications to the original recipe

If sufficient ingredient research isn’t done or product adjustments aren’t taken into account before manufacturing starts, various formula errors may arise during food processing.

The following are some frequent formula errors:

Incorrect ingredients – employing a less expensive replacement that doesn’t blend well with other tastes and altering how it combines with other food components during preparation. If food labels aren’t updated to ensure these modifications are based on nutritional values of items being mixed or modified by a percentage difference for batches manufactured between recipe revisions, this may lead to food labeling problems.

Even if an adequate effort was put into initially preparing specific recipes, undercooking/overcooking meals might affect nutritional content, resulting in incorrect nutrition facts.

How Changes in Suppliers Affect Food Packaging

With the increased focus on nutrition data these days, it’s critical that nutrition labeling be done correctly. Inadequate food labels lead consumers to believe they’re purchasing one product when buying another, but they may also put people’s health at risk if allergens aren’t identified on the label, and those with allergies ingest packaged foods.